The "before" picture. I picked this up at a garage sale a couple of weekends ago, envisioning more fabric storage space for my sewing room. It came at a drastically reduced price because "the leg was broken." Turns out the legs screw in, and it just needed to be tightened! I thought the seller would ask about $15 and I was prepared to offer $10. However...she started the bidding at $2. Yes, you read that correctly. $2!! I felt a counter-offer on my part was not really in order...

In case you are wondering, before I get started on my little tutorial, here is a bit of information. There is an interior height of 9 inches (not including lid and also not including the legs--when you add those it stands about 18 inches from floor to top of lid), width of 19 inches and depth of 16 1/2 inches.

The second thing you need to know is that I had a wild idea that I could "do it all by myself"--that thought probably stemming from the fact that I spend a lot of time with 3- and 4 1/2-year-old grandchildren and hear that phrase repeatedly. While it probably IS possible, I highly recommend having someone willing to help you. Mark generously agreed to be that someone.

Part 1: Deconstruction.

The idea is to take it apart, and then put it back together in the opposite order. The legs came off first. Mark made this cool little painting rack by drilling some holes in a scrap piece of lumber.

We had some charcoal spray paint with a metallic finish--nothing too glitzy and just the perfect color for the fabric we were using. I did purchase some Kilz primer in a spray can. Hated it. We thought we shook it up long enough but still it came out gloppy. If I were doing it again, I would just roughly sand the legs (as we did), skip the priming stage because it's not like the legs are getting a lot of wear or anything, and then just spray several coats of the finish paint. Because of the gloppiness, a couple of the legs didn't have a smooth finish, so we put them in the back of the stool.

Next we took off the hinges from the back and then all the little strips of wood that covered the raw edges of the fabric on the inside lid and bottom.

I can't tell you how gross this fabric was. It practically disintegrated when touched and made me feel the necessity of having hand sanitizer nearby. We removed all the staples and then used the fabric as a template.

This is what the lid and bottom looked like after we got all the fabric removed. The lid was padded with a little bit of foam; we used the original foam rather than replacing it.

Part 2: Putting it back together:

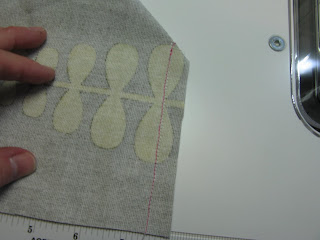

At this point, I laid my new fabric wrong side up, got out my sharpie pen and traced around the fabric we removed from the lid, cutting the same notches out of the four corners.

Next came the sewing. This is the ONLY sewing, and it involved matching the notched-out edges right sides together and sewing a 1/2-inch seam.

Each corner looked like this when it was turned right-side out again.

I did that to each corner and it fit like a glove over the top of the lid. This works great because otherwise you would have to do kind of a miter fold on the outside and staple or tack it down somehow. This eliminates all that fabric bulk. Then it just involved folding the raw edges to the inside of the lid, stapling it down, stapling the little wooden strips back on to cover the raw edges and, voila! Fabulous new lid.

Speaking of staple guns, I should mention that I had made the suggestion to Mark that perhaps a staple gun that attached to his air compressor might be a good idea. But you know how men DETEST the thought of going to the hardware store to purchase a new tool. So after

Moving on: The bottom fabric was one long strip. I measured the length and width of the old fabric, cut two pieces of the new fabric (matching the pattern), sewed one seam. Oops. I just said there was no more sewing involved. Okay. I had to sew these two pieces together to get the length I needed to go all the way around the outside. We kind of centered the fabric from top to bottom around the outside circumference of the bottom, so there was about an equal amount of fabric to fold around to the inside at the top of the box for stapling, and the same to fold under and staple on the bottom.

Hmmm. I'm beginning to like all these power tools!

Added the hinges on the back and screwed the legs back in (even that pesky "broken" leg).

Ready to see the finished project?

In its new home: my sewing room:

Want to see the best part? I KNEW this was the project for me when I opened it up and found this little plastic tray, which meant that it was a....

SEWING CHEST!!! I would have gladly paid $10 for this little beauty. I almost feel guilty that I got it for $2.

Almost...